Owner's Manual Model TG72K12 - AIR-COOLED GASOLINE ENGINE GENERATOR SET

←

→

Transcription du contenu de la page

Si votre navigateur ne rend pas la page correctement, lisez s'il vous plaît le contenu de la page ci-dessous

PREFACE

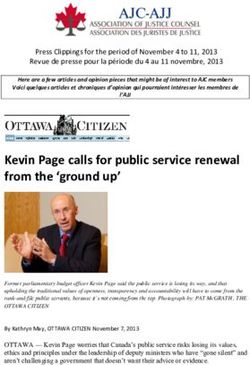

Thank you for purchasing products from EASTERN TOOLS & EQUIPMENT, INC. We appreciate your

business. The following manual is only a guide to assist you and is not a complete or comprehensive

manual of all aspects of maintaining and repairing your generator. The equipment you have purchased is

a complex piece of machinery. We recommend that that you consult with a dealer if you have doubts or

concerns as to your experience or ability to properly maintain or repair your equipment. You will save

time and the inconvenience of having to go back to the store if you choose to write or call us concerning

missing parts, service questions, operating advice, and/or assembly questions. Our gasoline generators

have some of the following features:

.Lightweight construction

.Air cooled

.Four-stroke gasoline internal combustion engine

.Recoil starter

.Large fuel tank

.Automatic voltage stabilizer

.NFB circuit protector

.AC outputs

.Low oil level sensor

Battery not included: Some brands you can use Champion 94b1, JBS 12N9-4B-1, MOTOCROSS

M2290B, NAPA 740-1869, POWERSONIC CB9-B

The ETQ air-cooled gasoline generators are widely used when electrical power is scarce. Our

generators provide a portable mobile solution in supplying power for field operations during project

construction.

This manual will explain how to operate and service your generator set.

If you have any questions or suggestions about this manual, please contact your local dealer or us

directly. Consumers should notice that this manual might differ slightly from the actual product as

more improvements are made to our products. Some of the pictures in this manual may differ

slightly from the actual product as well. Eastern Tools and Equipment, Inc. reserves the right to

make changes at any time without notice and without incurring any obligation.TABLE OF CONTENTS

Page

TECHNICAL SPECIFICATIONS AND DATA 1

EQUIPMENT DESCRIPTION & KNOWING YOUR GENERATOR 2

PACKAGE CONTENTS 3

Assembly 4

Instruction for the use of lifting bracket. 5

AUTO THROTTLE CONTROL SWITCH 6

Instruction for the use of RV adapter 6

Battery Assembly Procedure 7

SAFETY PRECAUTIONS 8

Electric shock and short circuit 8

Prevention from accidental burns 8

Refueling precautions 8

Engine safety precautions 9

Generator safety 9

PREPARATION BEFORE OPERATION 9

Engine oil 9

Air cleaner 11

GROUNDING THE GENERATOR 12

OPERATING THE GENERATOR 12

Starting the engine 12

Connecting electrical loads and electrical capacity 13

Stopping the engine 14

RECEPTACLES 15

MAINTENANCE 16

Cleaning the generator 17

Spark Plug 17

Storage 18

TROUBLESHOOTING 19

WIRING DIAGRAM 20

PART LISTINGS 21

Exploded Generator View 21

Crankcase 23

Push rod & Valve Rocker 24

Cylinder Head & Cylinder Head Cover Assembly 25

Crankcase Cover Assembly 26

Crankshaft, Piston & Tie-Rod 27

Carburetor Assembly & Air Cleaner Assembly 29

Flywheel & Recoil Starter 29

Ignition Coil 32

Regulating Control System 32

Starting Motor Assy 33

LIMITED WARRANTY 34

PRODUCT REGISTRATION CARD 34ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

TECHNICAL SPECIFICATIONS AND DATA

TG8250/TG72K12

Engine Type 4-stroke, Air-cooled, OHV

Displacement 420 cc(23.74 cu in)

Bore × Stroke 88×64 mm (3.5×2.5 in)

Max.Output 9.56 KW (13Hp)@ 3600 r/min

Max.Torque 2.7 kg-m(19.5 ft 1b)@2500rpm

Fuel Unleaded

Fuel Tank Capacity 24.32 Liters(6.42 gal)

Operation Hours 10Hrs @ 50% load

Engine Oil SAE 10W-30 or equivalent motor oil

Engine Oil Capacity 1.0L (33.8 Ounces)

Engine Start Pattern Manual start / Electric Start

Generator Type Synchronous generator

Phase Single

Power Factor Cos θ = 1.0

AC Output Voltage 120V/240V

AC Output Frequency 60Hz

AC Output Max Power 8250 ± 10% Watts

AC Output Rated Power 7250 ± 3% Watts

T.H.D < 5%

Noise Level 70 dB @ 7m

Product Weight 99 kg(218 lbs)

Product Dimensions 78.0×80.5×71.5 cm (30.71 x 31.69 x 28.15 in)

*Add oil to the engine when the “Oil Warning Light” is on.

*Engine might stop and may incur damage if oil is too low.

**Please refer to page 15 for receptacle power ratings.

1ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

EQUIPMENT DESCRIPTION & KNOWING YOUR GENERATOR

Please read this manual and follow the procedures covered in this manual. Become familiar with the

generators functions, applications, and limitations.

Below is a diagram of the locations of the various controls and functions of the generator

ILLUSTRATION OF CONTROLS

(1)

(2)

(28)

(3)

(27)

(4)

(5)

(26)

(6)

(7)

(25)

(8)

(24) (9)

(10)

(23)

(11)、(12)

(13)

(22)

(21) (19) (20) (18) (17) (16) (15) (14)

(1) FUEL TANK CAP (15) RUN TIME METER

(2) MUFFLER COMP (16) AUTO THROTTLE SWITCH

(3) CIRCUIT BREAKER(30A) (17) CAP ASSY,OIL FILLER

(4) CIRCUIT BREAKER(30A) (18) BOLT,PLUG,DRAIN

(5) SWITCH ASSY.,PANEL(32A) (19) OIL INDICATOR LIGHT ASSY

(6) 240/120V LOCKING RECEPTACLE L14-30 (20) STAY ASSY

(7) LUG GROUND (21) PUSHBUTTON ELECTRICITY STARTUP SWITCH

(8) 3-POLE RECEPTACLE L5-30R (22) STAND ASSY

(9) 120V RECEPTACLE 5-20R (23) STARTER ASSY,RECOIL

(10) FROTH WHEEL 10" (24) AIR/C ASSY

(11) WASHER,SPRING 12MM (25) COCK ASSY.FUEL

(12) NUT,FLANGE M12 (26) CHOKE SET ASSY

(13) BATTERY KICKSTAND (27) TANK COMP,FUEL

(14) CIRCUIT BREAKER(20A) (28) FRAME ASSY

WARNING: DO NOT exceed the generator’s wattage/amperage capacity. Our products are

continuously being changed and improved. Every effort has been made to ensure that information in

the manual is accurate and up to date. However, we reserve the right to change, alter or otherwise

improve the product and this manual at any time without prior notice.

2ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

PACKAGE CONTENTS

Your generator comes with the items listed below. Please check to see that all of the following items

are included with your generator.

If you are missing components DO NOT RETURN TO STORE, please call (888)908-6200 for

customer service.

Order No. Name Qty

1 Air-cooled generator set 1

Tool Kit:

Flat Head Screwdriver

Spark Plug Wrench

2 Wrench, 8×10,17×19 1

Bottle Wire

SWITCH PLUG

Assembly Kit:

3 1

Wheel (2 pcs)

Assembly Kit:

4 1

Wheel Kit Hardware

Assembly Kit:

5 1

Generator Foot (2 pcs)

etc.

Assembly Kit:

6 1

Handle

吊钩 Suspend

7 1

Conveyance Suspend

8 Owner’s manual 1

3ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

ASSEMBLY

Nut

U-Bolt

Washer

Axle

Nut

Wheel

Bolt+Nut

Foot

4ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Handle Bar Assembly

BOLT

·Secure the bracket bolt and nut.

·Make sure that the bracket is nicely tightened

down.

ABNORMITY

·Place the handle bar into the bracket.

·Secure with a bolt and nut

NUT

IMMOBILITY PIECE

HANDLE PIPE

Instruction for the use of the lifting bracket.

The lifting bracket is for lifting the generator which Step 3: Move it to the middle of the frame. (See

is described in the instruction manual, and it can below picture)

bear 3 to 3.5 times the net weight of the

generator.

Operation process:

Step 1: Take the lifting bracket attachment out of

the box and then enter it from the end of the frame

(see below picture).

Step 4: Lift the generator slowly.

Step 2: Move it towards the middle of the frame

(please note it does not interfere with or scratch

the fuel tank). (See below picture) Step 5: Remove the lifting bracket by following

(step 3→step 2→step 1) and then fasten it on the

frame as standby.

5ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

AUTO THROTTLE CONTROL SWITCH

When using the generator, leave the AUTO THROTTLE CONTROL SWITCH (ATC) in the “ON” position;

as soon as no output is need, engine will go into idle speed thus save fuel. As soon as, power is need,

engine will operate as normal again.

Photo of “ON” position:

Auto Throttle Switch

Instruction for the use of RV adapter

To use the attachment, the RV adapter is located in the attachments box. The adaptor should always be

coupled to the 3-pin receptacle (L5-30R) for the use of customers.

6ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Battery Assembly Procedure STEP 4

STEP 1

(+)

(+)

()

BOLT+NUT

STEP 5

BOLT

()

STEP 2

STEP 6 OK

STEP 3

BOLT

7ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

SAFETY PRECAUTIONS ELECTRIC SHOCK AND SHORT CIRCUIT

In order to ensure safety for the consumer, Be sure to notify the utility company when using

please carefully follow instructions on being the generator for backup power. Use approved

careful with the generators. transfer equipment to isolate the generator from

electric utility. In highly conductive area such as

Operate the generator ONLY outdoors. Never metal decking or steel work, use a ground

run the generator indoors as the engine gives circuit fault interrupter. Never touch the

off poisonous carbon monoxide, an odorless generator if the generator is wet. Also, never

and colorless gas. Inhaling carbon monoxide touch the generator if your hand is wet. Never

will cause nausea, fainting or death. Also, keep operate your generator if the weather

the generator at least 3 feet away from conditions call for any type of precipitation such

flammable matter for adequate ventilation. as rain, snow, or fog.

PREVENTION FROM ACCIDENTAL BURNS

Never touch the muffler and its cover when the

engine is running. Never touch the muffler and

cover after the engine has been used, as the

muffler remains hot for a good period of time.

REFUELING PRECAUTIONS

DANGER

Gasoline and its vapors are extremely

Always properly ground the generator. Failing flammable. Do not smoke near gasoline and

to do so can result in electrocution, particularly keep gasoline away from generator while the

if the generator is equipped with a wheel kit. generator is running. When adding fuel, turn the

generator off and let it cool at least 2 minutes

before removing the gas cap. Loosen gas cap

slowly to relieve the pressure in the tank.

Fill fuel tank outdoors and never overfill the

tank.

8ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

disconnecting electrical devices; make sure all

devices are in the "OFF" position before

disconnecting.

Operate the generator on level surfaces only.

Inclined surfaces reduce the effective

lubrication of the engine.

Do not expose the generator to excessive

moisture, dust, dirt, or corrosive vapors.

When storing gasoline or equipment with fuel in

tank. PREPARATION BEFORE

OPERATION

Store away from appliances or equipment that

have a pilot light or other ignition sources Before starting the generator, verify the

because it can ignite gasoline vapors. following conditions.

ENGINE SAFETY PRECAUTIONS ENGINE OIL

Do not touch hot surfaces. Allow equipment to • Fill the engine with SAE 10W-30 engine oil

fully cool down before touching. for generator use or follow the table below.

After the generator has been run, the engine

produces heat. The temperature of the muffler

and nearby areas can reach or exceed 1600 F.

Severe burns will occur on contact with skin. Do

not modify the generator in any way. The

generator supplies the rated voltage and rated

frequency at its governed speed.

GENERATOR SAFETY

Never overload your generator as this can

damage your generator or the electrical devices

connected to it

Do not start generator with electrical devices

connected to it. Start the generator first and

after the speed of the generator stabilizes,

electrical loads can be applied to it.

When connecting electrical loads, make sure • Make sure the generator is on a level

the devices are "OFF" first before connecting surface and make sure the oil dipstick is on

them. Keep the same concept when tight.

9ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

o Wash in solvent

GASOLINE o Squeeze

o Soak oil

o Squeeze dry

• Add unleaded gasoline and never fill the

fuel tank indoors. Also, be sure to install the

fuel tank cap on tight after filling.

• Reinstall the air cleaner element and

secure the cover by setting the cover

spring.

BATTERY(only for electric start models)

• DO NOT overfill the fuel tank. Always allow

room for fuel expansion. Never fill the fuel Charged Storage Batteries

tank when the engine is running or hot. Normal Charge

20Hour

Allow the unit to cool for two minutes before Voltage

Type Ratein First Stage Second Stage

(V)

refueling. DO NOT use light a cigarette or Amp-hr Amp Hours Amp Hours

smoke when filling the fuel tank.

GFM-21 12 21 1.5 10~12 1.0 8~10

AIR CLEANER

• Unsnap the air cleaner cover springs, and

remove the air cleaner cover.

• Check the air cleaner element to be sure

they are clean and in good condition.

• If the air filter is dirty, remove and clean the

element.

10ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

GROUNDING THE GENERATOR OPERATING THE GENERATOR

The National Electric Code requires that the STARTING THE ENGINE

frame of generator and the external electrically Before starting the engine, verify that the

conductive parts of the generator be connected engine oil is full, gasoline is full, and air Filter is

to an approved earth ground. Local codes may in place. Also, disconnect any load from the AC

differ and require other grounding specifications. receptacle, and turn the AC circuit breaker OFF

For this purpose, please use the ground wire (Figure 1)

that attaches from the frame to the generator

unit. Figure 1. Disconnecting electrical devices

• Turn the fuel valve to the "On" position

(Figure 2).

Using a No. 12 AWG (American Wire Gauge) Figure 2. Fuel Valve

stranded copper wire to the frame and to an

earth-driven copper or brass grounding rod

provides sufficient safety against shock.

However, local codes may differ. Contact a

local electrician to find out specifications for

grounding your generator.

Note: Note: Grounding your generator is highly

recommended. It helps prevent electrical shock • Place the choke lever in the “CHOKE”

if a ground fault condition exists in the position (Figure 3.).

generator or in faulty connected electrical

devices. Also, because the generator is rotating Figure 3. Engine switch on position

at high speeds, static electricity tends to buildup

within the unit. Grounding helps dissipate the

static electricity often building up in

underground devices.

• Turn the engine switch to the “ON” position

(Figure 4).

11ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Figure 4. Engine switch on position

• Turn the fuel valve to the “On” position (Figure 2).

• Pull the recoil starter grip lightly until

resistance is felt, then pull hard.Warning: Do

not allow the starter grip to snap back

against the engine.Return it gently (Figure

5.).

Figure 4. Recoil starting rope ·Place the choke lever in the “CHOKE” position

5

(Figure 3.).

• Turn the engine switch to the “ON” position

• Push the choke rod to the “OPEN” position a (Figure 4).

short distance at a time over several seconds as

the engine warms up (Figure 6).

Figure 4. Engine switch on position

ELECTRIC STARTING

Before starting the engine, verify that the engine oil

is full, gasoline is full, and air filter is in place. Also, • Push the choke rod to the “OPEN” position a

disconnect any load from the AC receptacle, and short distance at a time over several seconds as

turn the AC circuit breaker OFF (Figure 1). the engine warms up (Figure 5).

Figure1 .Disconnecting electrical devices

12ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

5 Table 1. Wattage reference chart

Additional

Rated

Surge

Tool or Appliance (Running)

(Starting)

Watts

Watts

Essentials

Light Bulb – 75 watt 75 -

Freezer 500 500

Sump Pump 800 1200

Refrigerator / Freezer – 18

CONNECTING ELECTRICAL LOADS AND 800 1600

Cu. Ft.

ELECTRICAL CAPACITY 1/3 HP Water Well Pump 1000 2000

Heating/Cooling

After starting the generator, let the engine warm Air conditioner – 10000 BTU 1200 1800

up after connecting electrical loads to it. Do not Window Fan 300 600

have any electrical loads connected before ½ HP Furnace Fan Blower 800 1300

starting the generator. Kitchen

1000 Watt Microwave Oven 1000 -

Coffee Maker 1500 -

Make sure all electrical devices are 60 Hz

Single element electric stove 1500 -

devices.

Hot plate 2500 -

Family Room

Do not connect 50 Hz devices to the generator.

DVD / CD Player 100 -

Do not connect 3-phase loads to the generator. VCR 100 -

Do not overload the generator. Stereo Receiver 450 -

27 “ Color Television 500 -

Before beginning your work, you must verify Personal Computer w/17”

800 -

that the rated (running) and surge (starting) monitor

wattage for the items you will power do not Other

exceed the operating capacity of the generator. Security system 180 -

Please refer to the following Table (1) for AM / FM clock radio 300 -

wattage / amperage ratings. Also, in order to ½ HP Garage door opener 480 520

40 Gallon electric water

prolong the life of your generator, sequentially 4000 -

heater

add loads and allow the generator to stabilize

DIY / Job Site

before adding another load. Never exceed the

Halogen work light 1000 -

capacity of the generator.

1/3 HP Airless sprayer 600 1200

Reciprocating Saw 960 960

Estimate how many surge (starting) watts you ½ HP Electric Drill 1000 1000

will need. Surge wattage is the short burst of 7 ¼ “ Circular saw 1500 1500

power needed to start electric motor-driven 10” Miter saw 1800 1800

tools or appliances such as a circular saw or 6” Table Planer 1800 1800

refrigerator. 10” Table saw / Radial arm

2000 2000

saw

1 ½ HP air compressor 2500 2500

Note: wattages listed are only approximates. Check

your electrical device for actual wattage.

13ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

STOPPING THE ENGINE • Turn the fuel valve to the "OFF" position

(Figure 4).

• Turn the AC circuit breaker to the "OFF"

position (Figure 1). Figure 4.

Figure 1.

• Unplug all the electrical loads from the

generator panel (Figure 2).

•

Figure 2.

• Let the engine run at no-load for several

minutes to stabilize the internal temperatures

of engine and generator.

• Turn the engine switch to the "OFF" position

(Figure 3).

Figure 3.

14ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

RECEPTACLES

This generator is equipped with the following

Receptacles

Figure 1. NEMA 5-20R: 125 Volt, 20 Amp

GFCI Duplex Receptacle

Figure 2. NEMA L5-30R: 125 Volt, 30 Amp

Receptacle

W

G

Figure 3. NEMA L14-30R: 240/120Volt,

30Amp Twist Lock Receptacle

X

W G

y

Note: Please be sure to use electrical cords that

support the amount of wattage being used.

The electrical cords should be able to handle 30

Amps of current at 125/250 Volts.

15ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

MAINTENANCE

Below is a routine maintenance schedule.

(1): These items should be serviced by a dealer.

(2): Every 3 years.

16ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

CLEANING THE GENERATOR

Generator maintenance consists of keeping the

unit clean and dry. Be sure to store the unit in a

clean and dry environment, where it will not be

exposed to excessive dust, dirt, moisture or any

corrosive vapors. Cooling slots should always

be clean and free from clogs.

Note: Do not use a garden hose to clean the

generator. Water can enter the fuel and intake Gap measurements

system, which cause problems. In addition, if 0.7~0.8 mm (.028~.031 inches)

water and dirt build up on the internal windings

of the generator, the resistance of these NOTE: If spark plug needs to be replaced, use

windings will decrease. NGK(or STAR) Brand: BPR6ES or F7(R)TC

• To clean the generator, use a damp cloth to

wipe the exterior surfaces.

• Use a soft bristle brush to loosen caked on

dirt of oil.

• Use a vacuum cleaner to pick up loose dirt

and debris.

• Compressed air (not to exceed 25 psi) may

be used to blow away dirt.

SPARK PLUG

• Remove the spark plug

• Remove the carbon deposits

• Check for discoloration. Standard is tan in

color.

• Check spark plug gap

17ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

STORAGE Figure 3.

The generator should be started at least once

every week. If this cannot be done and you

must store the unit more than 30 days, please

follow the following guidelines.

Close the fuel valve: drain the fuel from the fuel

tank (Figure 1).

Figure 1.

• Tighten the oil drain plug and fill the engine

with new oil to the filter neck (Figure 4).

Figure 4.

• Drain the fuel from the carburetor (Figure

2).

Figure 2.

• Pull the starter grip carefully until resistance is

felt (Figure 5).

Figure 5.

• Remove the oil filter cap and drain plug to

drain the oil (Figure 3).

• Store the generator in a clean area.

18ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

TROUBLESHOOTING

IMPORTANT: If trouble persists please call our customer help line at (888) 908-6200 M-F

8-5 Central Time.

Problem Cause Solution

Engine switch is set

Set engine switch to "on".

to "off".

Fuel valve is turned

Turn fuel valve to "open" position.

to "closed".

Choke is open. Close the choke

Engine is out of gas. Add gas.

Engine will not

Engine is filled with

start

contaminated or old Change the gas in the engine.

gas

Spark plug is dirty. Clean spark plug.

Spark plug is broken. Replace spark plug.

Generator is not on Move generator to a level surface to prevent low oil shutdown from

level surface. triggering.

Oil is low Add or replace oil.

Circuit reset button is Wait for 2 minutes and push the circuit reset button to the "on"

off. position.

Engine runs but Bad connecting

there is no If you are using an extension cord, try a different one.

wires/cables.

electrical output Bad electrical device

connected to Try connecting a different device.

generator.

Generator runs but Generator is

Try connecting fewer electrical loads to the generator.

does not support overloaded

all electrical Short in one of the

devices Try disconnecting any faulty or short-circuited electrical loads.

connected devices.

connected. Air cleaner is dirty. Clean or replace air cleaner.

19ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

WIRING DIAGRAM

20ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

PART LISTINGS

GENERATOR

NUMBER PART NUMBER DESCRIPTION QTY

1 19620-188-00 CONNECTION FLAT 1

2 31120-D70-00 STATOR COMP 1

3 31150-D70-00 STATOR COVER 1

4 31130-D70-00 ROTOR,COMP 1

5 31170-188-00 GENERATOR STAY 1

6 31203-188-00 BRACKET,RR.,MOTOR(BLACK) 1

7 19512-188-00 GENERATOR FAN 1

8 31160-188-00 BRUSH ASSY 1

9 30300-190-00 VOLTAGE REGULATOR (7KW) 1

10 95701-10285-00 FASTNESS BOLT(ROTOR)10×285 1

11 95701-05016-00 BOLT,FLANGE 5×16 1

12 95701-05016-00 BOLT,FLANGE 5×16 2

13 95701-05016-00 BOLT,FLANGE 5×16 2

14 95701-05016-00 BOLT,FLANGE 5×16 2

15 92101-05235-00 FLANGE BOLT(STATOR) 5×235 2

16 94111-05000-00 FLANGE BOLT(STATOR) M5 2

17 95701-06195-00 FLANGE BOLT(STATOR) 6×195 4

18 94111-10000-00 WASHER,SPRING(ROTOR) 10MM 1

19 90650-00300-00 BAND’WIRE(SINGLE) 300mm 2

21 91005-188-00 BEARING 6205RS 1

22 90305-05000-00 NUT (STATOR) M5 2

23 94112-05000-00 WASHER,SPRING 5MM 4

24 90486-05000-00 WASHER,PLAIN 4

21ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

FUEL TANK ASSEMBLY

NUMBER PART NUMBER DESCRIPTION QTY

1 16950-168-00 COCK ASSY.FUEL 1

2 95003-188-00 CLIP,TUBE (B8) 2

3 95001-188-00 TUBE,FUEL 4.5×205 1

4 17640-190-00 FUEL SENSOR ASSY 1

5 17620-168-00 CAP COMP,FUEL FILLER 1

6 15420-188-00 FUEL FILLER 1

7 17510-T80-00 TANK COMP,FUEL(BLUE) 1

8 95701-06012-00 BOLT,FLANGE M6X12 2

9 90486-06022-00 BOLT,FLANGE 6×22×2.0 2

10 53136-T80-00 IMMOBILITY PIECE(RUBBER) 2

MUFFLER ASSY. 10 9

8

1 12/13 4

11

3

2

5

7

6

NUMBER PART NUMBER DESCRIPTION QTY

1 18310-T80-01 MUFFLER COMP(SPARK ELIMINATE UTENSIL) 1

2 95701-08025-00 BOLT,FLANGE 8X25 2

3 18335-188-00 PIPE,EXH 1

4 18381-188-00 GASKET,MUFFLER 3

5 95701-06012-00 BOLT,FLANGE 6X12 7

6 18320-188-01 PROTR,OUT MUFFLER 1

7 18322-188-00 SAFEGUAR BOARD MUFFLER 1

8 18321-188-00 PROTR,IN MUFFLER 1

9 95701-08016-00 BOLT,FLANGE 8X16 4

10 18323-188-00 LATEX (PROTR,IN MUFFLER) 1

11 18382-188-00 MUFFLER STAY 1

12 90305-08000-00 NUT,FLANGE 8MM 2

13 94111-08000-00 WASHER,SPRING 8MM 2

22ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

FRAME&CONTROL PANEL

1

9/10

8

2

4/5/6

9

3 7

NUMBER PART NUMBER DESCRIPTION QTY

1 50310-T80-00 FRAME COMP 1

2 33100-T80-00 CONTROL PANEL ASSY 1

3 33120-188-00 CONTROL PANEL CASE 1

4 77320-188-00 BOTTOM RUBBER A 2

5 94050-08000-00 NUT FLANGE M8 4

6 94050-10000-00 NUT FLANGE M10 4

7 77330-188-00 BOTTOM RUBBER B 2

8 82350-T80-00 IMMOBILITY BOARD 1

9 95701-06012-00 BOLT FLANGE,6X12 8

10 94101-06000-00 WASHER,PLAIN(RED) 6MM 6

23ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

CRANKCASE

12

13

11

5 10

8

7

7

3 14

2

9

6 8

1

4

2

3

NUMBER PART NUMBER DESCRIPTION QTY

1 12000-190-00 CRANKCASE (HOLE) 1

2 92800-12016-00 BOLT,PLUG,DRAIN 12×16 2

3 94109-12000-00 WASHER,DRAIN PLUG,12MM 2

4 91201-188-00 OIL SEAL 34X52X8 1

5 96110-188-00 BEARING BALL RADIAL 6202 1

6 15510-188-00 SWITCH ASSY,OIL LEVEL 1

7 95701-06016-00 BOLT,FLANGE,6X16 2

8 44832-188-00 CLAMPER’METAL CABLE 1

9 95701-06012-00 BOLT,FLANGE,6X12 2

10 16541-188-00 SHAFT,GOVERNOR ARM 1

11 91203-168-00 OIL SEAL 8×14×5 1

12 90442-08000-00 WASHER,PLAIN.8MM(1.5MM) 1

13 94251-08000-00 PIN,LOCK 1

14 91201-188-00 OIL SEAL 34X52X8 1

24ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

PUSH ROD & VALVE ROCKER

11 10 8 7 5

1

4

16 15 14 14 13 9 8 6

2 3 3

16 15 13

2

12

NUMBER PART NUMBER DESCRIPTION QTY

1 14100-190-00 CAM SHAFT ASSY 1

2 14410-188-00 ROD,PUSH 5×165 2

3 14441-188-00 LIFTER VALVE 9×46 2

4 14711-188-00 VALVE,INLET

5 14721-188-00 VALVE,EXHAUST

6 12209-188-00 SEAL,VALVE STEM

7 14775-188-00 RETAINER,EXH VALVE DOWN SPRING

8 14751-188-00 SPRING,VALVE 2

9 14771-188-00 RETAINER,IN.VALVE SPRING

10 14773-188-00 RETAINER,EXH VALVE SPRING

11 14781-188-00 ROTATOR,VALVE

12 14791-188-00 PLATE,PUSH ROD GUIDE

13 14451-188-00 PIVOT,ROCKER ARM 2

14 14431-188-00 ARM,VALVE ROCKER 2

15 90012-188-00 BOLT PIVOT 2

16 90206-188-00 NUT,PIVOT ADJUSTING 2

25ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

CYLINDER HEAD & CYLINDER HEAD COVER ASSEMBLY

NUMBER PART NUMBER DESCRIPTION QTY

1 12210-190-00 HEAK ASSY CYLN 1

2 12204-188-00 GUIDE.IN,VALVE 1

3 12205-188-00 GUIDE ,EXH VALVE 1

4 90603-188-00 CLIP,GUIDE EXHAUST VALVE 1

5 12251-190-00 GASKET,CYLINDER HEAD 1

6 12310-188-00 COVER COMP,HEAD 1

7 12391-188-00 PKG,HEAD COVER 1

8 90035-08040-00 BOLT,STUD 8X40 2

9 95528-06060-00 ABNORMITY BOLT,FLANGE ASSY 6×60 1

10 90043-06110-00 BOLT,STUD M6XM8×110 2

11 94301-12020-00 DOWEL,PIN,12X20 2

12 95801-10080-00 BOLT,FLANGE 10×80 4

13 98097-188-00 SPARK PLUG F7TC 1

14 19631-188-00 LEAD WIND COVER 1

15 95701-06012-00 BOLT,FLANGE 6X12 1

16 91262-188-00 ABNORMITY LATEX 6MM 1

26ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

CRANKCASE COVER ASSEMBLY

NUMBER PART NUMBER DESCRIPTION QTY

1 11300-188-00 COVER ASSY.,CRANK CASE 1

2 11315-188-00 COVER DUCT 1

3 11381-188-00 PKG,CASE COVER 1

4 15620-188-00 CAP ASSY,OIL FILLER(YELLOW) 1

5 91301-188-00 O-RING 26×2.7 1

6 16512-188-00 HOLDER,GOV WEIGHT 1

7 90451-188-00 WASHER THRUST 6MM 2

8 90602-188-00 CLIP,GOV HOLDER 1

9 16513-188-00 PIN,GOVERNOR WEIGHT 1

10 16531-188-00 SLIDER,GOVERNOR 1

11 95701-05012-00 BOLT,FLANGE 5X12 3

12 91201-188-00 OIL SEAL 34X52X8 1

13 95701-08040-00 BOLT,FLANGE 8X40 6

14 95701-08040-00 BOLT,FLANGE 8X40 1

15 96110-188-00 BEARING BALL RADIAL 6202 1

16 96100-188-00 BEARING BALL RADIAL 6207 1

17 90701-08014-00 PIN DOWEL 8×14 2

27ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

CRANKSHAFT, PISTON & TIE-ROD

1 9 13

6 18 19

7 11 12 17

10 12

2 3 4 5 4

16

15

14

8 6

NUMBER PART NUMBER DESCRIPTION QTY

1 13010-190-00 RING SET,PISTON (STD) 1

2 13011-190-00 PISTON RING (A) 1

3 13012-190-00 PISTON RING (B) 1

4 13014-190-00 SIDE RING 2

5 13013-190-00 WAVE RING 1

6 90551-188-00 CLIP PISTON PIN 2

7 13101-190-00 PISTON 1

8 13111-188-00 PIN,PISTON 1

9 13200-190-00 CONN ROD ASSY 1

10 13201-190-00 TIE-ROD 1

11 13202-190-00 TIE-ROD COVER 1

12 90001-08038-00 BOLT,CONN.ROD 8×38 2

13 13315-190-00 COUNTERPOISE SHAFT 1

14 96100-188-00 BEARING,BALL RADIAL 6207 1

15 90741-188-00 WOODRUFF KEY 5×5×33 1

16 13311-190-00 CRANK SHAFT 1

17 23460-188-00 DRIVE GEAR 1

18 23470-188-00 TIMING DRIVING GEAR 1

19 13310-190-00 CRANK SHAFT COMP 1

28ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

CARBURETOR ASSEMBLY & AIR CLEANER ASSEMBLY

3 5 3

4

2

2-1 3

6

3

11 8

7 9

10

NUMBER PART NUMBER DESCRIPTION QTY

1 16100-190-00 CARBURETOR ASSY 1

2 16961-188-00 LATEX PIPE A 1

2-1 16962-188-00 LATEX PIPE B 1

3 95003-188-00 CLIP,TUBE (B8) 4

4 45460-188-00 BAND’WIRE,CHECK VALVE 1

5 16965-188-00 CHECK VALVE 1

6 16960-188-00 CHECK VALVE ASSY 1

7 16269-188-00 PKG,AIR/C 2

8 16221-188-00 PKG,CARB 1

9 16211-188-00 INSULATOR,CARB 1

10 16212-188-00 GASKET,INLET 1

11 16011-188-00 VALVE ASSY., SOLENOID 1

AIR CLEANER ASSY

2

2

5

6 1

4 3

NUMBER PART NUMBER DESCRIPTION QTY

1 17220-190-00 CASE COMP,AIR/C 1

2 94050-06000-00 NUT,FLANGE M6 2

3 17212-188-00 STAY,ELEMENT 1

4 17211-188-00 ELEMENT,AIR/C 1

5 17231-188-00 COVER,AIR/C 1

6 94010-188-00 WOOD BOLT FLANGE 1

29ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

RECOIL STARTER

6

5

4

7 3

2

2

2

1

NUMBER PART NUMBER DESCRIPTION QTY

1 28400-188-00 STARTER ASSY,RECOIL(BLACK) 1

2 95701-06008-00 BOLT,FLANGE,6X8 3

3 28410-188-00 CASE COMP RECOIL STARTER(BLACK) 1

4 28444-188-00 SETAINER, SPRING 1

5 28421-188-00 REEL,RECOIL STARTER 1

6 19610-188-00 COVER COMP.,FAN (BLACK) 1

7 95701-06012-00 BOLT,FLANGE,6X12 4

RECOIL STARTER

3

1

2

4

NUMBER PART NUMBER DESCRIPTION QTY

1 31110-190-00-FD FLYWHEEL COMP (2SLICE) 1

2 19511-188-00 FAN,COOLING 1

3 28451-188-00 STARTING CUP 1

4 94050-16000-00 NUT,SPECIALFLANGE M16×1.5-H24 1

30ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

IGNITION COIL

NUMBER PART NUMBER DESCRIPTION QTY

1 30500-190-00 COIL ASSY.,IGNIYION 1

2 30600-188-00 TERMINAL ASSY.,HIGE TENSION 1

3 44831-188-00-FD STAY LINE BOARD 1

4 30410-188-00 COIL,PULSER 1

5 35850-188-00 ELECTRICIZE WINDING 1

6 36101-188-00 CORD, STOP SWITCH 1

7 90650-188-00 BAND’WIRE 2

8 95701-06012-00 BOLT,FLANGE 6X12 1

9 95701-06030-00 BOLT,FLANGE 6X30 1

10 95701-06025-00 BOLT,FLANGE 6X25 2

REGULATING CONTROL SYSTEM

(12)

NUMBER PART NUMBER DESCRIPTION QTY

1 16550-188-00 REGULATING CONTROL SYETEM 1

2 16580-188-00 CONTROL ASSY (REMOTE) 1

3 16584-188-00 SPRING ,CONTROL ADJUSTING 1

4 93500-05035-00 SCREW,PAN 5×35 1

5 95701-06012-00 BOLT,FLANGE,6X12 2

6 16562-188-00 SPRING THROTTLE RETURN 1

7 16584-188-00 SPRING,CONTL ADJ 1

8 16555-188-00 ROD,GOVERRNOR 1

9 94050-06000-00 NUT,FLANGE 6MM 1

10 72880-06021-00 BOLT,GOV.ARM(T) 6×21 1

11 16551-190-00 ARM COMP., GOVERNOR 1

12 35810-188-00 ELECTROMAGNETISM VALVE,IDLE 1

31ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

STARTING MOTOR ASSY

NUMBER PART NUMBER DESCRIPTION QTY

1 31204-188-00 CONTACTOR ASSY 1

2 31206-188-00 ARMATURE COMP 1

3 31207-188-00 CLUTCH COMP.,OVERRUNNING 1

4 31210-188-00 MOTOR UNIT,STARTER 1

5 31211-188-00 BRACKET,CENTER 1

6 31212-188-00 BRACKET,FR 1

7 31213-188-00 GEAR,DRIVE PINION 1

8 31215-188-00 BRUSH 2

9 31218-188-00 YOKE COMP 1

10 31219-188-00 SPRING,BRUSH RETURN 4

11 31222-188-00 GEAR,REDUCTION 1

12 31213-188-00 HOLDER,BRUSH 1

13 31232-188-00 WIRE WATER COVER 1

14 31232-188-00 WIRE,WATER COVER 1

15 93892-05032-00 SCREW-WASHER 5×32 4

16 31233-188-00 INSULATOR 1

17 90110-188-00 SCREW-WASHER 4×6 1

18 91601-188-00 PACKING 1

19 93892-05014-00 SCREW-WASHER 4×6 2

20 94070-06080-00 NUT-WASHER 6MM 2

21 95701-08035-00 BOLT FLANGE 2

32ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

LIMITED WARRANTY

Eastern Tools & Equipment, Inc. will repair or replace, free of charge, any part or parts of the generator that are defective

in material or workmanship or both. Transportation charges on parts submitted for repair or replacement under this

Warranty must be borne by purchaser. This warranty is effective for the time period and subject to the conditions provided

for in this policy. For warranty service, find the nearest Authorized Service Dealer by contacting the place of purchase or

Eastern Tools & Equipment, Inc. THERE IS NO OTHER EXPRESSED WARRANTY. IMPLIED WARRANTIES,

INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE

YEAR FROM PURCHASE, OR TO THE EXTENT PERMITED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER ANY AND ALL WARRANTIES ARE EXCLUDED

TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some states do not allow limitations on how long an implied

warranty lasts, and some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you may also have

other rights, which vary from state to state.

Eastern Tools & Equipment, Inc.

WARRANTY PERIOD***

WITHIN U.S.A AND CANADA OUTSIDE U.S.A. AND CANADA

ENGINES CONSUMER COMMERCIAL CONSUMER COMMERCIAL

USE USE USE USE

GASOLINE

1 year 90 days 1 year 90 days

GENERATOR

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of

time stated in the table above. “Consumer use” means personal residential household use by a retail consumer. “Commercial use” means

all other uses, including the commercial, income producing or rental purpose. Once the engine has experienced commercial use, it shall

thereafter be considered as a commercial use engine for purpose of this warranty. Engines use in competitive racing or commercial

or rental tracks are not warranted.

***A two-year warranty applies to the emission control system on engines certified by EPA and CARB.

IMPORTANT

“WARRANTY REGISTRATIONS IS NECESSARY TO OBTAIN LIMITED WARRANTY ON EASTERN TOOLS & EQUIPMENT, INC.,

ENGINES. THE WARRANTY REGISTRATION CARD MUST BE RETURNED WITHIN 15 DAYS OF PURCHASE FOR LIMITED

WARRANTY TO BE VALID”

About Your Product Warranty

Eastern Tools & Equipment, Inc. welcomes warranty repair and apologizes to you for being inconvenienced. Any Authorized Service

Dealer may perform warranty repairs. Most warranty repairs are handled routinely, but sometimes warranty service may be inappropriate.

For example, warranty would not apply if an engine is damaged because of misuse, lack of routine maintenance, shipping, handling,

warehousing and improper installation. Similarly, warranty is void if the serial number on the engine has been removed or if the engine

has been altered or modified. If a customer differs with the decision of the Service Dealer, an investigation will be made to determine

whether the warranty applies. Ask the Service Dealer to submit all supporting facts to his Distributor or the factory for review. If the

distributor or the factory decides that the claim is justified, the customer will be fully reimbursed for those items that are defective. To

avoid misunderstanding, which might occur between the customer and the dealer, listed below are some of the causes of engine failure

that the warranty does not cover.

33ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Normal wear:

Engines and generators, like all mechanical devices, need periodic parts service and replacement to perform well. Warranty will not cover

repair when normal use has exhausted the life of a part of an engine.

Improper maintenance:

The life of an engine or your equipment depends upon the conditions under which it operates, and the care it receives. Some applications,

such as tillers, pumps, and rotary movers, are very often used in dusty or dirty conditions, which can cause what appears to be premature,

wear. Such wear, when caused by dirt, dust, spark pug cleaning grit, or other abrasive material that has entered the engine because of

improper maintenance is not covered by warranty.

This warranty cover engine related defective material and/or workmanship only, and not replacement or refund of the

equipment to which the engine may be mounted. Nor des the warranty extend to repairs required because of:

1. Problems caused by parts that are not original eastern tools & equipment, inc., parts.

2. Equipment controls or installations that prevent starting, cause unsatisfactory engine performance, or shorten engine life.

(Contact equipment manufacturer.)

3. Leaking carburetor, clogged fuel pipes, sticking valves, or other damage, caused by using contaminated or stale fuel. (Use

clean, fresh, lead-free gasoline.)

4. Parts which are scored or broken because an engine was operated with insufficient or contaminated lubricating oil, or and

incorrect grad of lubricating oil (check oil level daily or after every 8 hours of operation. Refill when necessary and change at

recommended intervals.) Engine damage may occur if oil level is not properly maintained. Read Operating & Maintenance

Instructions.

5. Repair or adjustment of associated parts or assemblies such as clutches, transmissions, remote controls, etc., which are not

manufactured by Eastern Tools & Equipment, Inc.

6. Damage or wear to parts caused by dirt, which entered the engine because of improper air filter maintenance, re-assembly, or

use of a non-original air filter element or cartridge. Read Operating & Maintenance Instructions.

7. Parts damaged by over-speeding, or overheating caused by grass, debris, or dirt, which plugs or clogs the cooling fins, or

flywheel are, or damaged caused by operating the engine in a confined area without sufficient ventilation.

8. Engine or equipment parts broken by excessive vibration caused by a loosen cutter blades unbalanced blades or loose

unbalanced impellers, improper attachment of equipment to engine crankshaft, over speeding or other abuse in operation.

9. A bent or broken crankshaft, caused by striking a solid object with the cutter blade of a rotary lawn mower, or excessive v-belt

tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e., combustion chamber, valves, valve seats, valve guides, or burned starter motor

winding, caused by the alternated fuels such as, liquefied petroleum, natural gas, altered gasoline’s etc.

Warranty is available only through service dealers, which have been authorized by Eastern Tools & Equipment, Inc., please

contact the place of purchase or Eastern Tools & Equipment, Inc. for a Service Dealer near you.

34ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

CALIFORNIA & USEPA EMISSION CONTROL WARRANTY STATEMENT

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board (CARB) and Eastern Tools & Equipment, Inc. are

pleased to explain the Federal and California Emission Control System Warranty on your small nonroad engine. In California, new small

nonroad engines must be designed, built and equipped to meet the State’s stringent and anti-smog standards. Eastern Tools &

Equipment, Inc. must warrant the emission control system on your small nonroad engine for the periods of time listed above listed above

provided there has been no abuse, neglect or improper maintenance of your small nonroad engine.

Your emission control system may include parts such as the carburetor, or fuel-injection system, the ignition system and catalytic

converter. Also included may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, Eastern Tools & Equipment, Inc. will repair your small nonroad engine at no cost to you including

diagnosis, parts and labor.

OWNER’S WARRANTY RESPONSIBILITIES

As the small nonroad engine owner, you are responsible for the performance of the required maintenance listed in your Owner’s Manual.

Eastern Tools & Equipment, Inc. recommends that you retain all receipts covering maintenance on your small nonroad engine, but

Eastern Tools & Equipment, Inc. cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all

scheduled maintenance.

As the small nonroad engine owner, you should, however, be aware that Eastern Tools & Equipment, Inc. may deny you warranty

coverage if your; small nonroad or part thereof has failed due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small nonroad engine to Eastern Tools & Equipment, Inc. distribution center as soon as a

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities or request warranty service you should contact either the

place of purchase or Eastern Tools & Equipment, Inc., c/o Service Manager, Engine and Equipment Service Division.

IMPORTANT NOTE:

This warranty statement explains your rights and obligations under Emission Control system Warranty (ECS Warranty), which is provided

to our by Eastern Tools & Equipment, Inc. pursuant to California law, Eastern Tools & Equipment, Inc. also provides to original purchasers

of new Eastern Tools & Equipment, Inc. engines. Eastern Tools & Equipment, Inc. Limited Warranties for New engines & other Equipment

associated with the engine (Eastern Tools & Equipment, Inc. Products Warranty), which is enclosed with all New Eastern Tools &

Equipment, Inc. engines and products on a separate sheet. The ECS Warranty applies only to the emission control system of your new

engine. To the extent that there is any conflict in terms between the ECS Warranty and the Eastern Tools & Equipment, Inc., Warranty, the

ECS Warranty shall apply except in any circumstances in which the Eastern Tools & Equipment, Inc. Product Warranty may provide a

longer warranty period. Both the ECS Warranty and the Eastern Tools & Equipment, Inc. product Warranty describe important right and

obligations with respect to your new engine.

Eastern Tools & Equipment, Inc. at its location in Ontario, California can perform warranty service or any authorized service dealer near

you. At the time of requesting warranty service, evidence must be presented of the date of sale to the original purchaser. The purchaser

shall pay any charges for transporting the product to and from the place when the inspection and/or warranty preformed. The purchaser

shall be responsible for any damage or loss incurred in connection with the transportation of any engine or any part(s) thereof submitted

for inspection and/or warranty work.

If you have any questions regarding your warranty rights and responsibilities, you should contact Eastern Tools & Equipment, Inc.

35ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

PRODUCT REGISTRATION

For more efficient customer service, please fill out the information below and mail to Eastern Tools &

Equipment, Inc. Product Warranty and Registration Division.

Model No._________________ Engine Serial No.____________ Purchase Date ____/____/_____

Purchased from:

[ ] Retail Location [ ] Private Consumer [ ] Other_________________________________________

Name_________________________________________________________________________________

Address_______________________________________________________________________________

Telephone (____)____-________ Purchase Price____________

Purchased: [ ] New [ ] Used

Consumer Information:

Name___________________________________________________ Telephone (____) ____ - _________

Street Address__________________________________________________ Suite or Apt No.___________

City______________________________________________ State_______ Zip Code_________________

Province or County______________________________________________________________________

Are you a: [ ] Business [ ] Residence

Product Usage Information:

How often will you use this product?

[ ] Everyday [ ] Periodically [ ] Emergency Use Only [ ] Other

What type of application will you use this product in?

[ ] Heavy Commercial [ ] Moderate Commercial [ ] Light Commercial [ ] Tradeshows

[ ] Heavy Residential [ ] Moderate Residential [ ] Light Residential [ ] Camping/Backpacking

[ ] Other________________________________________________________________________

Important information:

It is critical to your warranty that the original point of sales receipt the retained by current consumer, and in

order to comply with Eastern Tools &Equipment Product Warranty statement you must return the registration

card within 15 days of original purchase Product warranty is valid from original date of purchase.

Please mail the above card to: Eastern Tools & Equipment, Inc.

111 Bluegrass Dr.

Norwalk, OH 44857

36ETQ

EASTERN TOOLS & EQUIPMENT INC Tel: (888)908-6200 Web Site: easterntools.com

Guide d'utilisation – Modèle TG72K12

GROUPE ÉLECTROGÈNE À MOTEUR À ESSENCE REFROIDI PAR AIR

37PRÉFACE

Merci d'avoir acheté des produits chez EASTERN TOOLS & EQUIPMENT, INC. Nous

apprécions faire affaire avec vous. Le présent guide a uniquement pour but de vous

assister et n'est pas un manuel complet ou exhaustif touchant tous les aspects de

l'entretien et de la réparation de votre génératrice. L'équipement que vous avez acheté est

une pièce d'équipement complexe. Nous vous recommandons de consulter un

concessionnaire si vous avez des hésitations ou des préoccupations concernant votre

expérience à pouvoir faire l'entretien ou la réparation de votre équipement. Vous

épargnerez du temps et l'inconvénient d'avoir à retourner au magasin si vous choisissez de

nous appeler ou de nous écrire concernant pièces manquantes, questions de service,

conseils à propos de l'exploitation et/ou questions sur les assemblages. Nos groupes

électrogènes à essence comprennent certaines des caractéristiques ci-après :

.Légèreté de construction

.Refroidissement à air

.Moteur quatre-temps à combustion interne d'essence

.Lanceur à rappel

.Grand réservoir à essence

.Régulateur de tension automatique

.Protection de circuit par disjoncteur

.Sorties en c.a.

.Capteur de bas niveau d'huile

Les groupes électrogènes à essence ETQ refroidis par air sont largement utilisés lorsque

l'alimentation électrique se fait rare. Nos génératrices offrent une solution mobile portable

pour la fourniture d'alimentation électrique au cours des opérations sur le terrain durant les

projets de construction.

Le présent guide explique comment utiliser et faire l'entretien de votre groupe électrogène.

Pour toute question ou suggestion à propos du présent guide, veuillez contacter votre

concessionnaire local ou communiquer directement avec nous. Les consommateurs

prendront note que le présent guide peut différer légèrement du produit réel étant

donné que nous apportons constamment des améliorations à nos produits.

Certaines des images incluses dans ce manuel peuvent également différer

légèrement du produit réel. Eastern Tools and Equipment, Inc. se réserve le droit de

faire des modifications en tout temps sans préavis ni obligation quelle qu'elle soit.TABLE DES MATIÈRES

Page

CARACTÉRISTIQUES ET DONNÉES TRECHNIQUES 1

DESCRIPTION DE L'ÉQUIPEMENT ET CONNAISSANCE DE VOTRE GÉNÉRATRICE 2

CONTENU DE L'EMBALLAGE 3

ASSEMBLAGE 4

CONSIGNES DE SÉCURITÉ 6

Chocs électriques et court-circuits 6

Prévention contre les brûlures accidentelles 6

Précautions au remplissage 6

Consignes de sécurité à propos du moteur 7

Sécurité et groupes électrogènes 7

PREPARATION AVANT L'EXPLOITATION 7

Huile moteur 7

Filtre à air 8

GROUNDING THE GENERATOR 9

MISE À LA TERRE DE LA GÉNÉRATRICE 9

Démarrage du moteur 9

Branchement de la charge électrique et capacité électrique 10

Arrêt du moteur 11

PRISES 12

ENTRETIEN 13

Nettoyage de la génératrice 14

Bougie 14

Entreposage 15

DÉPANNAGE 16

SCHÉMA DE CÂBLAGE 17

LISTES DE PIÈCES 18

Génératrice 18

Ensemble de réservoir à essence 19

Ens. de silencieux 19

Châssis et panneau de commande 20

Carter 21

Tige-poussoir et culbuteur de soupape 22

Culasse et ensemble de couvre-culasse 23

Ensemble de couvercle de carter 24

Vilebrequin, piston et bielle 25

Ensemble de carburateur et ensemble de filtre à air 26

Lanceur à rappel et volant moteur 27

Bobine d'allumage 28

Système de contrôle du régulateur 28

GARANTIE RESTREINTE 29

CARTE D'ENREGISTREMENT DU PRODUIT 32ETQ

EASTERN TOOLS & EQUIPMENT INC Tél.: 1-888-908-6200 Site Web : easterntools.com

CARACTÉRISTIQUES ET DONNÉES TECHNIQUES

TG72K12/TG8250

Type de moteur Quatre-temps, refroidi par air, soupapes en tête

Cylindrée 389cc (23,74 po cu)

Alésage × Course 88×64 mm (3,5×2,5 po)

Puissance maximale 9,56KW (13 Hp) @ 3600 tr/min

Couple maximum 2,7 kg-m (19,5 pi lb) @ 2500 tr/min

Carburant Sans plomb

Contenance du réservoir 24.32litres (6,42 gal)

Durée de fonctionnement en heures 10hres @ charge de 50 %

Huile moteur SAE 10W-30 ou huile moteur équivalente

Capacité d'huile moteur 1,0 L (33,8 oz)

Schéma de démarrage moteur Démarrage manuel

Type de génératrice Alternateur

Phase Monophasé

Facteur de puissance Cos θ = 1,0

Tension de sortie c.a. 120 V / 240 V

Fréquence de sortie c.a. 60 Hz

Puissance de sortie c.a. maximale 8250 ± 10 % watts

Puissance nominale de sortie c.a. 7250 ± 3 % watts

T.H.D < 5%

Niveau de bruit 70dB @ 7 m

Poids du produit 99 kg(218 lb)

Dimensions du produit 78,0×80,5×71,5 cm (30,71 x 31,69 x 28,15 po)

*Ajouter de l'huile au moteur lorsque que le témoin d'alerte d'huile est allumé.

*Le moteur pourrait s'arrêter et subir des dommages si le niveau d'huile est trop bas.

**Veuillez vous référer à la page 15 pour les puissances nominales des prises.

1ETQ

EASTERN TOOLS & EQUIPMENT INC Tél.: 1-888-908-6200 Site Web : easterntools.com

DESCRIPTION ET CONNAISSANCE DE VOTRE GÉNÉRATRICE

Veuillez lire le présent guide et suivre les procédures qu'il renferme. Familiarisez-vous avec les fonctions,

les applications et les limitations de cette génératrice.

Voici un schéma des emplacements de différentes commandes et fonctions de la génératrice :

ILLUSTRATION DES COMPOSANTS

(1)

(2)

(28)

(27) (3)

(4)

(5)

(26)

(6)

(25) (7)

(8)

(24) (9)

(10)

(23)

(11) (12)

(22) (13)

(21) (19) (20) (18) (17) (16) (15) (14)

(1) COMPOSANT CADRE (15) CALCULAGRAPH ACL

(2) COMPOSANT SILENCIEUX (16) ENS. COMMANDE DE RALENTI

(3) DISJONCTEUR (30 A) (17) ASS. BOUCHON, ORIFICE REMPLISS. D'HUILE

(4) DISJONCTEUR (30A) (18) BOUCHON DE VIDANGE D′HUILE

(5) PANNEAU, ASS. D'INTERRUPTEUR (32 A) (19) ENS. TÉMOIN LUMINEUX NIV. D'HUILE

(6) PRISE VERROUILLABLE 120/240V L14-30R (20) ENS. DE SOCLE

(21) INTERRUPTEUR À POUSSOIR DE DÉMARREUR

(7) Cosse de mise à la terre

ÉLECTRIQUE

(8) 3-POLE RÉCEPTACLE L5-30R (22) ENS. DE POIGNÉE

(9) PRISE 120 V 5-20R (23) ENS. DÉMARREUR À RAPPEL

(10) PNEU BALLON 10" (24) ENS. ROBINET D'ESSENCE

(11) Plateau De Batterie (25) Valve De Carburant

(12) ÉCROU, FLASQUE M12 (26) ENS. ÉTRANGLEUR

(13) ESSIEU DE ROUE (27) COMP. BOUCHON, ORIFICE DE REMPLISS. CARB.

(14) DISJONCTEUR (20 A) (28) COMPOSANT CADRE

AVERTISSEMENT : NE PAS dépasser la capacité de puissance/intensité de la génératrice. Nos

produits sont constamment modifiés et améliorés. Tous les efforts sont faits afin de faire en sorte que

l'information contenue dans le guide soit exacte et à jour. Toutefois, nous nous réservons le droit de

modifier, altérer ou autrement améliorer le produit et le présent guide en tout temps sans avis préalable.

2ETQ

EASTERN TOOLS & EQUIPMENT INC Tél.: 1-888-908-6200 Site Web : easterntools.com

CONTENU DE L'EMBALLAGE

Votre génératrice est accompagnée des articles répertoriés ci-après. Veuillez vérifier si tous les

articles ci-après sont inclus avec votre génératrice.

S'il vous manque des composants, NE RETOURNEZ PAS AU MAGASIN, veuillez plutôt appeler

le service à la clientèle au 1-888-908-6200.

Commande nº Nom Qté

1 Ensemble de génératrice refroidie par air 1

Jeu d'outils :

Tournevis à lame plate

Clé à bougie

2 Clé, 8×10, 17×19 1

Cordon à bouteille

SWITCH PRISE

Ensemble prêt-à-monter :

3 1

Roue (2 pces)

Ensemble prêt-à-monter:

4 Quincaillerie pour jeu de roues 1

Ensemble prêt-à-monter:

5 Embase de génératrice (2 1

pces)

etc.

Ensemble prêt-à-monter:

6 1

Poignée

Suspend

7 1

Conveyance Suspend

8 Guide d'utilisation 1

3ETQ

EASTERN TOOLS & EQUIPMENT INC Tél.: 1-888-908-6200 Site Web : easterntools.com

ENSEMBLE

Ensemble de jeu de roues/embase

Remarque:

• Le jeu de roues doit être installé alors que la génératrice est sèche.

• Placer la génératrice sur le côté (côté moteur)

• Fixer l’essieu à l’aide de deux boulons en U.

•Visser les écrous sur les boulons en U pour Écrou

fixer l’essieu.

•Placer la rondelle sur l’essieu. Boulon en U

Rondelle

Essieu

• Placer la roue sur l’essieu.

• Serrer la roue solidement à l’aide d’un Écrou+rondell

écrou.

Roue

• Utiliser le boulon et l’écrou fournis pour fixer

solidement l’embase au châssis de la

Boulon et écrou

génératrice.

• Replacer la génératrice à sa position verticale

normale.

• Vous êtes maintenant prêt à installer les

guidons.

Embase

4Vous pouvez aussi lire